Z42Tc型耐磨陶瓷閘閥PN16~PN100更新日期:2013-09-17

主要性能參數

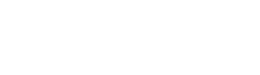

主要外形及結構尺寸

| 型號 | PN |

工作壓力 (Mpa) |

適用溫度 (℃) |

適用介質 | 材料 | ||||

| 閥體 | 閥蓋 | 閘板 | 閥桿 | 閥座 | |||||

| Z42Tc-16C | 16 | 1.6 | ≤425 |

水、油品、 汽、酸液、 渣水 |

WCB | WCB |

WCB+ 工程陶瓷 |

2Cr13 | 工程陶瓷 |

| Z42Tc-25 | 25 | 2.5 | |||||||

| Z42Tc-40 | 40 | 4.0 | |||||||

| Z42Tc-63 | 63 | 6.3 | |||||||

| Z42Tc-100 | 100 | 10.0 | |||||||

| Z42Tc-16I | 16 | 1.6 | ≤540 | ZGCr5Mo | ZGCr5Mo |

ZGCr5Mo +工程陶瓷 |

25Cr2MoV | ||

| Z42Tc-25I | 25 | 2.5 | |||||||

| Z42Tc-40I | 40 | 4.0 | |||||||

| Z42Tc-63I | 63 | 6.3 | |||||||

| Z42Tc-100I | 100 | 10.0 | |||||||

| Z42Tc-16P | 16 | 1.6 | ≤200 |

ZG1Cr18- Ni9Ti |

ZG1Cr- 18Ni9Ti |

ZG1Cr- 18Ni9Ti+ 工程陶瓷 |

1Cr18Ni9Ti | ||

| Z42Tc-25P | 25 | 2.5 | |||||||

| Z42Tc-40P | 40 | 4.0 | |||||||

| Z42Tc-63P | 63 | 6.3 | |||||||

| Z42Tc-100P | 100 | 10.0 | |||||||

主要外形及結構尺寸

| DN | L | D | D1 | D2 | b-f | z×Φd | H | Do | 重量/kg |

| 15 | 130 | 95 | 65 | 45 | 16-2 | 4×Φ14 | 170 | 120 | 5 |

| 20 | 150 | 105 | 75 | 55 | 16-2 | 4×Φ14 | 190 | 140 | 6.5 |

| 25 | 160 | 115 | 85 | 65 | 16-2 | 4×Φ14 | 205 | 160 | 9 |

| 32 | 180 | 135 | 100 | 78 | 18-3 | 4×Φ18 | 270 | 180 | 12 |

| 40 | 200 | 145 | 110 | 85 | 18-3 | 4×Φ18 | 310 | 200 | 26.5 |

| 50 | 250 | 160 | 125 | 100 | 18-3 | 8×Φ18 | 358 | 240 | 29 |

| 65 | 265 | 180 | 145 | 120 | 18-3 | 8×Φ18 | 373 | 240 | 33 |

| 80 | 280 | 195 | 160 | 135 | 20-3 | 8×Φ18 | 435 | 280 | 45 |

| 100 | 300 | 215 | 180 | 155 | 20-3 | 8×Φ23 | 500 | 300 | 63 |

| 125 | 325 | 245 | 210 | 185 | 22-3 | 12×Φ23 | 614 | 320 | 108 |

| 150 | 350 | 280 | 240 | 210 | 24-3 | 12×Φ25 | 674 | 360 | 134 |

| 200 | 400 | 335 | 295 | 265 | 26-3 | 12×Φ25 | 818 | 400 | 192 |

| 250 | 450 | 405 | 355 | 320 | 30-3 | 16×Φ25 | 969 | 450 | 273 |

| 300 | 500 | 460 | 410 | 375 | 30-4 | 16×Φ30 | 1145 | 560 | 379 |

| 350 | 550 | 520 | 470 | 435 | 34-4 | 20×Φ30 | 1280 | 640 | 590 |

| 400 | 600 | 580 | 525 | 485 | 36-4 | 20×Φ34 | 1452 | 640 | 850 |

| 450 | 650 | 640 | 585 | 545 | 40-4 | 20×Φ41 | 1541 | 720 | 907 |

| 500 | 700 | 705 | 650 | 608 | 44-4 | 24×Φ41 | 1676 | 720 | 958 |

| 600 | 800 | 840 | 770 | 718 | 48-4 | 24×Φ41 | 1874 | 800 | 1112 |

| DN | L | D | D1 | D2 | b-f | z×Φd | H | Do | 重量/kg |

| 15 | 130 | 95 | 65 | 45 | 16-2 | 4×Φ14 | 170 | 120 | 5.5 |

| 20 | 150 | 105 | 75 | 55 | 16-2 | 4×Φ14 | 190 | 140 | 7 |

| 25 | 160 | 115 | 85 | 65 | 16-2 | 4×Φ14 | 205 | 160 | 11 |

| 32 | 180 | 135 | 100 | 78 | 18-2 | 4×Φ18 | 270 | 180 | 14 |

| 40 | 200 | 145 | 110 | 85 | 18-3 | 4×Φ18 | 310 | 200 | 30 |

| 50 | 250 | 160 | 125 | 100 | 20-3 | 4×Φ18 | 358 | 240 | 34 |

| 65 | 265 | 180 | 145 | 120 | 22-3 | 8×Φ18 | 373 | 240 | 36 |

| 80 | 280 | 195 | 160 | 135 | 22-3 | 8×Φ18 | 435 | 280 | 50 |

| 100 | 300 | 230 | 190 | 160 | 24-3 | 8×Φ23 | 500 | 300 | 69 |

| 125 | 325 | 270 | 220 | 188 | 28-3 | 8×Φ28 | 614 | 320 | 116 |

| 150 | 350 | 300 | 250 | 218 | 30-3 | 8×Φ28 | 674 | 360 | 141 |

| 200 | 400 | 360 | 310 | 278 | 34-3 | 12×Φ25 | 818 | 400 | 192 |

| 250 | 450 | 425 | 370 | 332 | 36-3 | 12×Φ30 | 969 | 450 | 207 |

| 300 | 500 | 485 | 430 | 390 | 40-4 | 16×Φ30 | 1145 | 560 | 400 |

| 350 | 550 | 550 | 490 | 448 | 44-4 | 16×Φ34 | 1280 | 640 | 631 |

| 400 | 600 | 610 | 550 | 505 | 48-4 | 16×Φ34 | 1452 | 640 | 900 |

| 450 | 650 | 660 | 600 | 555 | 50-4 | 20×Φ34 | 1541 | 720 | 1013 |

| 500 | 700 | 730 | 660 | 610 | 52-4 | 20×Φ41 | 1676 | 720 | 1166 |

| 600 | 800 | 840 | 770 | 718 | 56-4 | 20×Φ41 | 1874 | 800 | 1258 |

| DN | L | D | D1 | D2 | D6 | b-f | z×Φd | H | Do | 重量/kg |

| 15 | 130 | 95 | 65 | 45 | 40 | 16-2 | 4×Φ14 | 135 | 120 | 6 |

| 20 | 150 | 105 | 75 | 55 | 51 | 16-2 | 4×Φ14 | 190 | 140 | 8 |

| 25 | 160 | 115 | 85 | 65 | 58 | 16-2 | 4×Φ14 | 205 | 160 | 12 |

| 32 | 180 | 135 | 100 | 78 | 66 | 18-2 | 4×Φ18 | 270 | 180 | 15 |

| 40 | 200 | 145 | 110 | 85 | 76 | 18-3 | 4×Φ18 | 310 | 200 | 31 |

| 50 | 250 | 160 | 125 | 100 | 88 | 20-3 | 4×Φ18 | 371 | 280 | 34 |

| 65 | 280 | 180 | 145 | 120 | 110 | 22-3 | 4×Φ18 | 391 | 280 | 39 |

| 80 | 310 | 195 | 160 | 135 | 121 | 22-3 | 8×Φ18 | 455 | 320 | 52 |

| 100 | 350 | 230 | 190 | 160 | 150 | 24-3 | 8×Φ18 | 511 | 360 | 80 |

| 125 | 400 | 270 | 220 | 188 | 176 | 28-3 | 8×Φ23 | 628 | 400 | 127 |

| 150 | 450 | 300 | 250 | 218 | 204 | 30-3 | 8×Φ25 | 708 | 400 | 154 |

| 200 | 550 | 375 | 320 | 282 | 260 | 38-3 | 8×Φ25 | 885 | 450 | 263 |

| 250 | 650 | 445 | 385 | 345 | 313 | 42-3 | 12×Φ30 | 906 | 560 | 368 |

| 300 | 750 | 510 | 450 | 408 | 364 | 46-4 | 16×Φ34 | 1203 | 640 | 547 |

| 350 | 850 | 570 | 510 | 465 | 422 | 52-4 | 16×Φ34 | 1341 | 640 | 679 |

| 400 | 950 | 655 | 585 | 535 | 474 | 58-4 | 16×Φ4 | 1492 | 720 | 953 |

| DN | L | D | D1 | D2 | D6 | b-f | z×Φd | H | Do | 重量/kg |

| 15 | 170 | 105 | 75 | 55 | 41 | 18-2 | 4×Φ14 | 140 | 100 | 7 |

| 20 | 190 | 125 | 90 | 68 | 51 | 20-2 | 4×Φ18 | 140 | 100 | 9 |

| 25 | 210 | 135 | 100 | 78 | 58 | 22-2 | 4×Φ18 | 215 | 180 | 12 |

| 32 | 230 | 150 | 110 | 82 | 66 | 24-2 | 4×Φ23 | 270 | 180 | 16 |

| 40 | 240 | 165 | 125 | 95 | 76 | 24-3 | 4×Φ23 | 345 | 200 | 32 |

| 50 | 250 | 175 | 135 | 105 | 88 | 26-3 | 4×Φ23 | 470 | 200 | 39 |

| 65 | 280 | 200 | 160 | 130 | 110 | 28-3 | 8×Φ23 | 520 | 250 | 43 |

| 80 | 310 | 210 | 170 | 140 | 121 | 30-3 | 8×Φ23 | 570 | 300 | 60 |

| 100 | 350 | 250 | 200 | 168 | 150 | 32-3 | 8×Φ25 | 700 | 300 | 89 |

| 125 | 400 | 295 | 240 | 202 | 176 | 36-3 | 8×Φ30 | 780 | 350 | 140 |

| 150 | 450 | 340 | 280 | 240 | 204 | 38-3 | 8×Φ34 | 850 | 350 | 207 |

| 200 | 550 | 405 | 345 | 300 | 260 | 44-3 | 12×Φ34 | 1035 | 400 | 325 |

| 250 | 650 | 470 | 400 | 352 | 313 | 48-3 | 12×Φ41 | 1050 | 560 | 467 |

| 300 | 750 | 530 | 460 | 412 | 364 | 54-4 | 16×Φ41 | 1470 | 640 | 590 |

| DN | L | D | D1 | D2 | D6 | b-f | z×Φd | H | Do | 重量/kg |

| 15 | 170 | 105 | 75 | 55 | 40 | 20 | 4×Φ14 | 140 | 120 | ﹣ |

| 20 | 190 | 125 | 90 | 68 | 51 | 22 | 4×Φ18 | 140 | 120 | 13 |

| 25 | 210 | 135 | 100 | 78 | 58 | 24 | 4×Φ18 | 215 | ﹣ | 20 |

| 32 | 230 | 150 | 110 | 82 | 66 | 24 | 4×Φ23 | 270 | ﹣ | 60 |

| 40 | 240 | 165 | 125 | 95 | 76 | 26 | 4×Φ23 | 345 | ﹣ | 50 |

| 50 | 250 | 195 | 145 | 112 | 88 | 28 | 4×Φ25 | 470 | 360 | 70 |

| 65 | 280 | 220 | 170 | 138 | 110 | 32 | 8×Φ25 | 520 | 400 | 100 |

| 80 | 310 | 230 | 181 | 148 | 121 | 34 | 8×Φ25 | 570 | 400 | 110 |

| 100 | 350 | 265 | 210 | 172 | 150 | 38 | 8×Φ30 | 700 | 560 | 180 |

| 125 | 400 | 310 | 250 | 210 | 176 | 42 | 8×Φ34 | 780 | 560 | 250 |

| 150 | 450 | 350 | 290 | 250 | 204 | 46 | 12×Φ34 | 850 | 560 | 360 |

| 200 | 550 | 430 | 360 | 312 | 260 | 54 | 12×Φ41 | 1035 | ﹣ | ﹣ |

| 250 | 650 | 500 | 430 | 385 | 313 | 60 | 16×Φ48 | 1050 | ﹣ | ﹣ |

| 300 | 750 | 585 | 500 | 442 | 364 | 70 | 16×Φ41 | 1470 | ﹣ | ﹣ |

注:本公司是上海閥門生產廠家,生產的閥門種類調節閥,球閥,蝶閥,閘閥,減壓閥,止回閥,疏水閥,截止閥,旋塞閥,閥,節流閥,水力控制閥等,其中閘閥分為,電動閘閥,氣動閘閥,手動閘閥,刀閘閥,法蘭閘閥,平板閘閥,不銹鋼閘閥,軟密封閘閥,硬密封閘閥等,工程師皆有數十年經驗,歡迎您來電洽談業務!